HARNESSING HORSEPOWER ON SYDNEY HARBOUR – CAPTAIN COOK CRUISES

Project Details

• Elizabeth Class Passenger Catamarans – Quickshift MGX5114SC ratio 2.04:1 with Twin station EC300 controls

• Jillian Class Rocket Passenger Catamarans – Quickshift MGX5095a ratio 1.81:1 with single station EC300 controls

• Tubby Class Passenger Catamarans – Quickshift MGX5075IV ratio 1.99 with single station EC300 controls

• Maggie Cat Passenger Catamarans – Twin Disc MG6557SC ratio 2.48 with three station EC300 controls

About Captain Cook Cruises

Captain Cook Cruises Australia is proud to be part of the SeaLink Travel Group connecting the nation’s icons and best tour experiences to the world. Captain Cook Cruises began in Sydney in 1970 and for nearly five decades has proven to be the market leader and premier Sydney Harbour cruise line. Their fleet of restaurant, sightseeing, ferry and sailing vessels offer an exciting range of public cruises and private charters for 2 to 2,000 guests.

Some of their guests and events have included the Pope, the Presidents of China and the United States of America, Vice Chancellor of Germany, members of the British Royal family, the American basketball `Dream Team’; Incentives for Ford, Amway, Mazda and Nissan; the Supreme and Federal Courts Judges Conference, Commonwealth Games Fundraising Dinners and the Oprah audience – to name just a few.Captain Cook Cruises Australia are proud to have provided employment opportunities for thousands of young Australians, many of whom have gone on to become leaders in their fields including actor Hugh Jackman.

TWIN DISC SUPPLY & SERVICE Q&A |

|

ANTHONY HAWORTH DAVID GARRETT MANAGING DIRECTOR MARINE MANAGER |

HOW MANY HOURS DO YOUR BOATS OPERATE EACH YEAR?

Our ferries operate up to 14 hours a day and for as much as 5,000 hours a year.

WHAT IS CRITICAL WITH REGARDS TO PERFORMANCE AND RELIABILITY CONSIDERING THE AMOUNT OF HOURS YOUR BOATS ARE OPERATING EACH YEAR?

Based on the time that our ferries operate and the tight timetables we maintain we just have to have complete confidence that each and every product in the vessels works. We need to have complete confidence and reliance that the systems will do their job.

WHY DID YOU CHOOSE THE TWIN DISC TRANSMISSIONS AND CONTROLS FOR YOUR VESSELS?

We’ve used Twin Disc products before and we know they are “bullet proof”. We know how long the systems last and we can plan accurately our service expectations, which is critical in limiting downtime. We’d actually tried some competitors products in the past and had been let down, so it made the decision to use Twin Disc a lot easier. We also know that if something does go wrong we can get the support we need from Jason, Tor and the Twin Disc team. What’s also critical is that our Skippers and Operators know they can rely on the Twin Disc products, which gives them a lot of satisfaction. We know that the Twin Disc products just perform.

HOW HAVE THE TWIN DISC PRODUCTS PERFORMED?

Almost faultlessly, no operational or maintenance concerns for us.

WHAT HAS THE SALES AND AFTER-SALES SERVICE EXPERIENCE BEEN LIKE FROM TWIN DISC?

After sales service has been great. We know if we have a problem that we will get the support we need in a timely manner.

Boating forever changed

The Twin Disc QuickShift® transmission system has forever raised boaters’ expectations of their crafts’ performance — and their own. No other transmission offers such shifting speed, smoothness, slow speed control, precision boat handling and safety. Combined with the Twin Disc EC300 Electronic Controls, the QuickShift system provides unparalleled boat control under all conditions. One for all Twin Disc  designed the QuickShift system from the ground up to be a totally integrated system of transmission, valves, actuators and controls — all engineered to precisely fit and work together. This engineering elegance and resulting performance and reliability cannot be duplicated by competitive products utilizing add-on components. It all comes from Twin Disc — one system, one manufacturer and single-source support.

designed the QuickShift system from the ground up to be a totally integrated system of transmission, valves, actuators and controls — all engineered to precisely fit and work together. This engineering elegance and resulting performance and reliability cannot be duplicated by competitive products utilizing add-on components. It all comes from Twin Disc — one system, one manufacturer and single-source support.

BOATING WORLD

The Transmission

The QuickShift transmission line combines the renowned Twin Disc pedigree of  performance and reliability with new, patented actuation technology. We didn’t simply take our traditional transmission design and add electronic gizmos to simulate the performance we wanted. We re-engineered our transmissions to incorporate and integrate a unique clutch, actuation system and electronic controls. This total design concept resulted in a transmission that not only responds so much faster and smoother than any other transmission, it offers easily customizable shifting parameters and adjustments.

performance and reliability with new, patented actuation technology. We didn’t simply take our traditional transmission design and add electronic gizmos to simulate the performance we wanted. We re-engineered our transmissions to incorporate and integrate a unique clutch, actuation system and electronic controls. This total design concept resulted in a transmission that not only responds so much faster and smoother than any other transmission, it offers easily customizable shifting parameters and adjustments.

It shifts so fast…

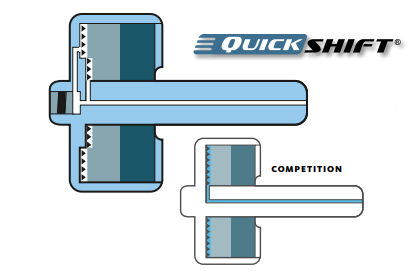

To accomplish a faster and smoother clutch engagement, QuickShift utilizes a sequenced engagement that operates automatically by design and does not need any adjustment. In the first stage of the engagement it makes up to 80% of the maximum oil pressure available to 20% of the clutch piston area, where conventional clutches have to get filled completely at four to five times lower pressure.

This allows the clutch to fill much faster, thereby reducing the shift response time dramatically. Only then does a sequencing valve allow oil flow to the complete clutch piston area to fully engage the transmission.

The small difference between the already high torque transfer capability achieved at this stage to full torque provides for a very smooth and seamless engagement.

Think how much more propulsion control that gives you. There’s never been anything like it. The patented Twin Disc QuickShift design offers in excess of 15 times faster clutch response and in excess of 10 times faster to full torque. The Twin Disc QuickShift with its patented GP valve engages in 0.05 seconds, compared to a standard marine transmission’s 0.75 seconds, due to clutch fill time. QuickShift achieves full torque in .2 seconds, compared to a standard transmission requiring 2.0 seconds.

A Twin Disc QuickShift transmission with e-Troll has a clutch response after approximately 0.05 seconds, even when operating in trolling mode. This is in excess of 100 times faster than any conventional transmission with a conventional trolling valve. Simply put, the QuickShift system shifts a lot faster than you do under any conditions.

The remarkable GP ValveThis is the building block of the QuickShift actuation system. The Twin Disc-developed GP valve combines advanced hydraulics with electronic technology, forming an actuation system consisting of two proportional solenoids and electronic profile generator (rate of rise). This simple, “bulletproof” design comprises just 21 off-theshelf parts. The engineering used does not require any adjustment due to extreme tolerances required by delicate components. It’s robust, reliable, and effective. No shims, no springs, no orifices are required to install it nor to adjust it. This means there are no installation or setup issues for the boat builder or boat operator.

Competitive systems use a hydraulic/mechanical rate of rise, where clutch pressures are ever changing due to environmental conditions, and can only be adjusted by shims and springs. Now you have exact engagement control of the QuickShift transmission, with instant translation of control signals into solenoid commands and electronic rate of rise. It signals Not In Neutral and Manual Override modes. It monitors the clutch for overheating, especially handy for protection in troll mode. It disables engagement at low voltage and provides other diagnostic and protection capabilities. If service is ever needed, it can be done outside the valve by adjusting the main pressure or by replacing the controller. This dramatically reduces labor hours for service work. You don’t need to buy an extra trolling valve to get trolling performance. Just add the Twin Disc e-Troll controller to the GP valve and you’ve got superior trolling capability. For an extra measure of reliability, the Twin Disc QuickShift system comes equipped with a mechanical override.

Competitive systems use a hydraulic/mechanical rate of rise, where clutch pressures are ever changing due to environmental conditions, and can only be adjusted by shims and springs. Now you have exact engagement control of the QuickShift transmission, with instant translation of control signals into solenoid commands and electronic rate of rise. It signals Not In Neutral and Manual Override modes. It monitors the clutch for overheating, especially handy for protection in troll mode. It disables engagement at low voltage and provides other diagnostic and protection capabilities. If service is ever needed, it can be done outside the valve by adjusting the main pressure or by replacing the controller. This dramatically reduces labor hours for service work. You don’t need to buy an extra trolling valve to get trolling performance. Just add the Twin Disc e-Troll controller to the GP valve and you’ve got superior trolling capability. For an extra measure of reliability, the Twin Disc QuickShift system comes equipped with a mechanical override.

The Ultimate Propulsion Control

The QuickShift transmission and GP valve, combined with the sophisticated EC300 Electronic Control System, is the ultimate control configuration. It provides you fingertip, single-lever control of engine speed, prop speed and direction plus instant full power — or any desired degree between idle and full — as fast as the engine can respond. Factor in propeller control down to 50 RPM or one knot boat speed and just imagine how much easier and safer docking or any slow-speed maneuvering will be.

While the EC300 system is fully compatible with all popular propulsion options, it has been specifically engineered to operate with QuickShift and is the only control system approved to operate the QuickShift Express® mode.

While the EC300 system is fully compatible with all popular propulsion options, it has been specifically engineered to operate with QuickShift and is the only control system approved to operate the QuickShift Express® mode.

Express Joystick System®

The Twin Disc Express Joystick System (EJS™) absolutely revolutionizes docking and slowspeed maneuvering of diesel powered, conventional driveline boats. With easy fingertip movements you control direction and speed — instantaneously. No lagging. No lugging. No lurching. No clunking. The EJS smoothly and simultaneously actuates and controls engines, transmissions and thrusters. You can effortlessly move the boat in any direction and even pivot it on its own axis. Once you try it, you can’t imagine driving your next boat without it.

The Twin Disc Express Joystick System (EJS™) absolutely revolutionizes docking and slowspeed maneuvering of diesel powered, conventional driveline boats. With easy fingertip movements you control direction and speed — instantaneously. No lagging. No lugging. No lurching. No clunking. The EJS smoothly and simultaneously actuates and controls engines, transmissions and thrusters. You can effortlessly move the boat in any direction and even pivot it on its own axis. Once you try it, you can’t imagine driving your next boat without it.

Dynamic Positioning Systems

The Twin Disc DP propulsion control package allows instantaneous, shockless and virtually constant forward and reverse shifting to keep supply vessels on station as directed by the craft’s dynamic positioning system. Drivelines can execute directional reversals at variable torque levels more than 30 times per minute to hold station with the full requirements of the DP class.

The Twin Disc DP propulsion control package allows instantaneous, shockless and virtually constant forward and reverse shifting to keep supply vessels on station as directed by the craft’s dynamic positioning system. Drivelines can execute directional reversals at variable torque levels more than 30 times per minute to hold station with the full requirements of the DP class.

No other marine transmission compares to the Twin Disc QuickShift in performance, reliability and precision slow-speed control. Just ask your boat builder, engine packager or Twin Disc marine distributor.

Click to download the project overview.